Système de chambres d’essai d’émissions EK mRack

L’information demandée n’est malheureusement disponible qu’en anglais. Cependant, chez Olfasense nous avons des employés qui parlent français. Veuillez nous informer si vous préférez continuer la conversation en français.

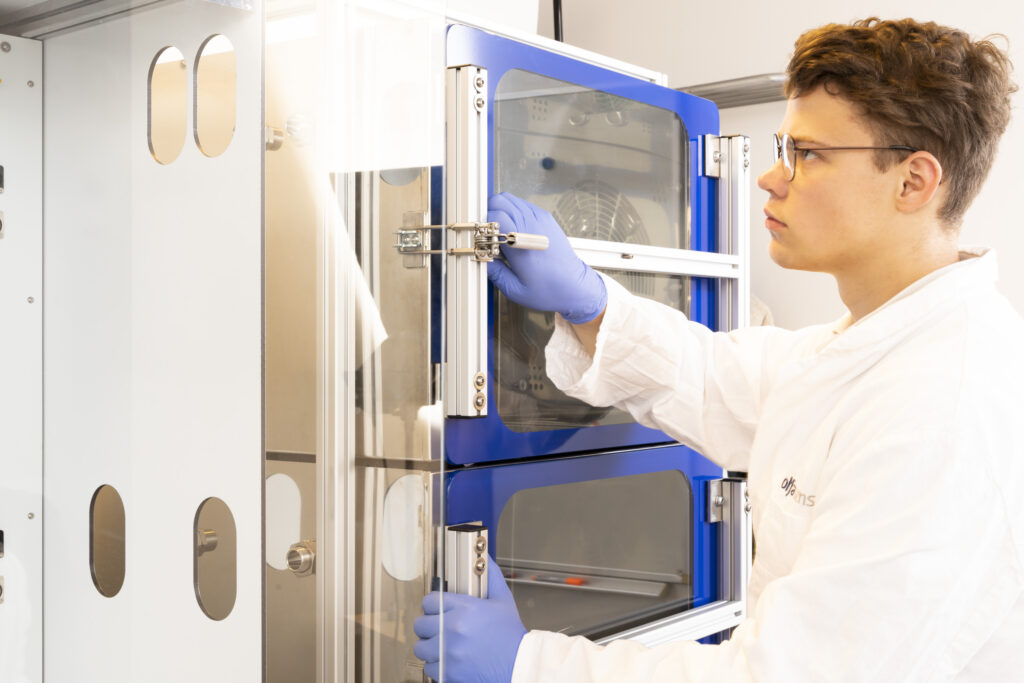

The Olfasense VOC emission test chamber system EK mRack allows the characterization of the emissions of volatile organic compounds under precise test conditions.

Depending on the volume of the VOC emission test chamber, the EK mRack complies fully with the requirements of ISO 16000-9, EN 16516, EN 717-1, as well as the GEV Testing Method.

With a typical testing period of 28 days, the EK mRack allows for several tests to run in parallel, which enormously increases the efficiency of your everyday laboratory work.

Key facts

- VOC emission test chamber rack system with up to 6 VOC emission test chambers

- Available chamber volumes: 110 l, 125 l, 225 l, 250 l, 500 l (other volumes optionally available); max. 1500 l for all chambers combined

- Compact, robust, competitively priced

- „Emission-free“ test chamber

- High accuracy and performance of all normative parameters

- One volume flow sensor for checking the leak tightness and one flow velocity sensor for checking the air velocity above the test specimen

Standard compliance

- ISO 16000-9 (VOC emissions from building products and furnishing)

- EN 16516 (VOC emissions from construction products)

- EN 717-1 (Formaldehyde emissions from wood-based panels)

- GEV – testing method (VOC emissions from products for flooring installation, adhesives and building materials)

Configure your EK mRack to meet your specific needs

The modular rack system consists of a base unit with the possibility to connect one or two chamber racks.

Each rack can be equipped with up to 3 VOC emission test chambers in sizes 110 l, 125 l, 225 l, 250 l and 500 l. These sizes can be flexibly combined. This allows you to individually configure your EK mRack to meet your specific needs.

The modular design also allows you to add a second chamber rack at a later stage, should you decide to connect only one rack initially.

Due to the compact design, the EK mRack can be rolled through common door sizes on steering castors. The individual chamber racks and the base unit are delivered separately and can be assembled at the installation site with little effort.

EK mRack base unit

- Possibility to connect one chamber rack on both sides, each with up to three VOC emission test chambers

- Control for one mass flow controller per chamber to regulate the air exchange

- Individual fan speed control for up to 6 chambers

- Central humidity control (30 to 70% rel. H) for synchronous conditioning of up to 6 chambers

- One volume flow sensor for checking the leak tightness and one flow velocity sensor for checking the air velocity above the test specimen

- PLC control unit including Ethernet interface

- Touch Panel 15,6“; 1920 x 1080 pixels

- Integrated central connection for fume hood for chamber exhaust air

Available VOC test chambers

- Usable space (LxHxW) of the different VOC emission test chambers:

- 110 l: 319 x 444 x 590mm

- 125 l: 375 x 444 x 590mm

- 225 l: 759 x 444 x 590mm

- 250 l: 852 x 444 x 590mm

- 500 l: 852 x 890x 590mm

- Stainless steel chamber with glass door

- Minimized adhesion

- User-friendly door locks

- Enclosed rotor with drive (speed adjustable)

- Precise compliance with all standard requirements for the VOC emission test chamber

- Process monitoring sensors (temperature and humidity)

- Mass flow controller for supply air control

- Sampling connection with a Swagelok connector and three expansion slots

Technical data

Other connections optionally available