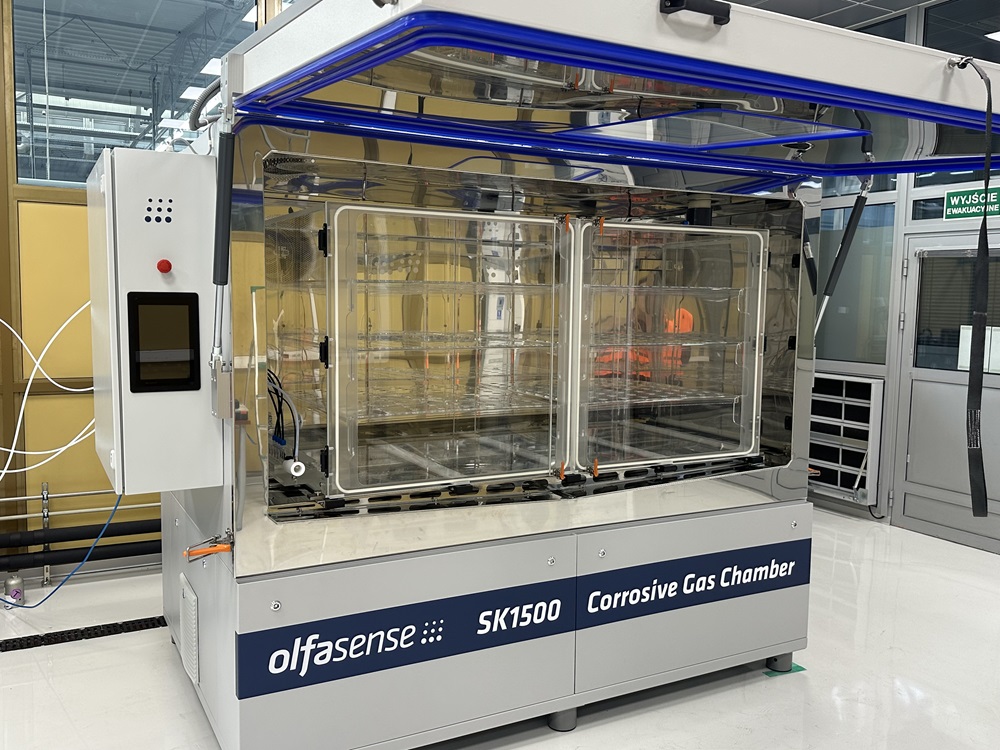

Câmara de ensaios de gases corrosivos SK1500C

Com a câmara de ensaios de gases corrosivos SK1500C, integrámos com êxito este sistema de dosagem de gases corrosivos numa câmara climática CTS para garantir uma simulação climática padronizada e, assim, permitir uma indução de corrosão reproduzível.

A sua tecnologia de refrigeração é inteiramente concebida com compressores de CO₂, tornando-a particularmente ecológica e compatível com a versão mais recente do Regulamento de Gases Fluorados.

Com um excelente desempenho e um volume de teste de 1500 litros em até 3 níveis, a câmara de ensaios de gases corrosivos SK1500C não é apenas uma das maiores câmaras de ensaios de gases corrosivos do mercado, mas também de mais elevada qualidade, permitindo-lhe aumentar com eficiência as suas medições de gases corrosivos.

Dosagem simultânea de até 4 gases corrosivos

A SK1500C tem um recipiente amovível feito de plástico transparente e resistente à corrosão (PMMA) e pode ser equipada com até 4 linhas de dosagem individuais. Isso permite tanto a realização de testes de corrosão com gases individuais como a dosagem simultânea de até 4 gases corrosivos. A câmara climática CTS também pode ser usada para outros testes, bastando remover o recipiente de PMMA.

O nosso sistema de dosagem de gases corrosivos pode ser facilmente adaptado e integrado em diferentes câmaras climáticas de vários tamanhos. Graças a esta adaptabilidade, temos a capacidade de lhe oferecer soluções extremamente versáteis que podem ser personalizadas com precisão, de acordo com as suas necessidades específicas e as condições de uma ampla variedade de ambientes de teste.

Saiba mais sobre o Sistema de dosagem de gases corrosivos – kit de instalação.

Tecnologia de refrigeração altamente ecológica

A tecnologia de refrigeração das câmaras climáticas CTS é inteiramente concebida com compressores de CO₂, sendo, desta forma, particularmente ecológica.

O motivo subjacente é a mais recente versão do Regulamento de Gases Fluorados, que proibirá a comercialização de “sistemas de refrigeração autónomos” com um valor de PAG >150 a partir de 2025.

Isto significa que os refrigerantes usados até ao momento (R23, R452a, R449a, etc.) deixarão de ser permitidos. O único refrigerante não-inflamável permitido será o CO₂.

A solução de CO₂ da CTS proporciona os seguintes recursos e vantagens:

- Arrefecimento com refrigerante natural CO₂ (R744)

- O CO₂ não é tóxico nem inflamável

- O CO₂ está disponível de forma fácil e ilimitada em todo o mundo a muito baixo custo

- Tecnologia comprovada

- Não requer arrefecimento estático

- Baixos volumes de enchimento

- Não requer teste de deteção de fugas para o circuito de refrigeração de CO₂

Características principais

- Resultados ideais graças à dosagem de gases corrosivos de alta precisão com recurso a um controlador de fluxo de massa de alta qualidade.

- Injeção ideal dos gases corrosivos no jato livre do gás transportador e homogeneização por expansão do difusor antes da entrada na câmara de ensaios. Como consequência, mesmo as concentrações mais baixas na ordem de 10 ppb misturam-se de forma homogénea e são introduzidas na câmara de ensaios na concentração especificada.

- Monitorização contínua das taxas de renovação do ar e das concentrações de gás de acordo com três parâmetros independentes, com desligamento automático quando os parâmetros do processo são ultrapassados. Entre estes, o registo e o controlo da pressão interna da câmara de ensaios, a taxa de entrada do ar transportador, a taxa de fornecimento de ar da dosagem de gás corrosivo e as características do ventilador em relação à velocidade.

- Regulação da taxa de renovação do ar através de um sensor de fluxo na entrada da câmara de ensaios de gases corrosivos. Isto garante concentrações corretas de acordo com a norma correspondente quando os gases corrosivos entram na câmara de ensaios, evitando que as concentrações ultrapassem o valor padrão.

- Software especialmente desenvolvido para a aplicação de testes de gases corrosivos, que guia o utilizador, de forma intuitiva, ao longo das etapas individuais do processo.

- Visão clara do material de teste graças às janelas de vidro acrílico de alta qualidade (polimetacrilato de metilo) que proporcionam um meio de observação transparente.

- Conformidade com as normas de teste líderes do setor, como IEC 60068-2-60, IEC 60068-2-42/43 e outras, para garantir resultados de teste confiáveis.

Características de desempenho

- Gases passíveis de testes: ácido sulfídrico (H2S), dióxido de enxofre (SO2), cloro (Cl2) com gás transportador N2, dióxido de azoto (NO2) com gás transportador de ar sintético e outros

- Dosagem de até quatro gases corrosivos com 4 linhas de dosagem de gases corrosivos entre 1-100 ml/min

- Um dispositivo de segurança integrado monitoriza a pressão para um funcionamento sem falhas

- Ligação para recolha de amostras de gás para análise posterior

- Possibilidade de testar a concentração de gases corrosivos com ar seco ou nitrogénio

Testemunhos

Especificações técnicas

2200 x 1150 x 1100 mm (BxTxH)

1850 x 900 x 900 mm (BxTxH)